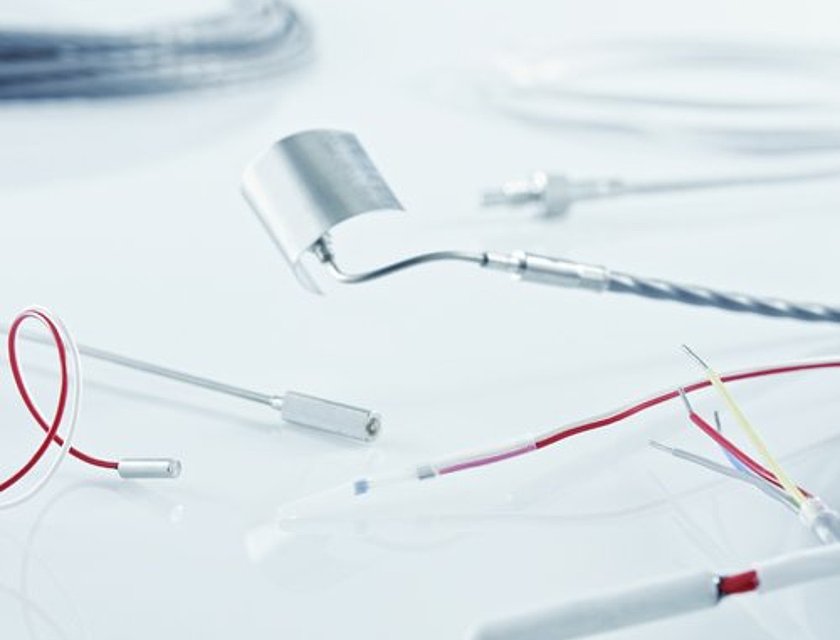

Sensors for wind power plant equipment suppliers, manufacturers and service companies

Ever larger plants, ever harder-to-reach offshore plants under more critical operating conditions all demand maximum reliability and safety from all components. Reliable continuous temperature monitoring is extremely significant here. Installed as standard, classic winding head sensors and bearing and slot resistance thermometers serve to monitor the operating temperature in generators or gears and drives.

Your specialist for wind power plant temperature sensors

We are constantly gathering and expanding our extensive temperature monitoring expertise for a wide range of wind power plant concepts. Increasing power has changed the requirements for monitoring and analysis, so that many different types of temperature sensor are now used for the various monitoring tasks in wind power plants. We develop our own product ideas and discuss them with potential customers. EPHYMESS sees itself as a problem solver and development partner for its customers. The prototypes are field tested by our customers or approved for use following first article inspection in line with the standard.

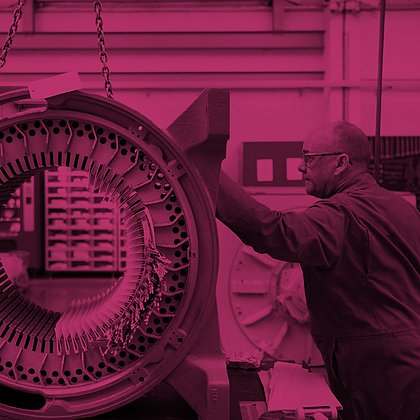

Wide range of installation positions

Wind power plants are complex systems. A whole series of components needs temperature monitoring in order to guarantee permanent plant safety; unplanned idle times need to be avoided, maintenance intervals optimised and the plant life expectancy guaranteed. Numerous measuring points need thermal monitoring:

- External temperature and nacelle temperature

- Switchgear cabinet and its electronics

- Transformer and generator

- Central lubrication system

- Pitch drives of the rotor blades

- Azimut drives of the nacelles

- Gears and bearings

- Brakes