At a glance

Assembly variants

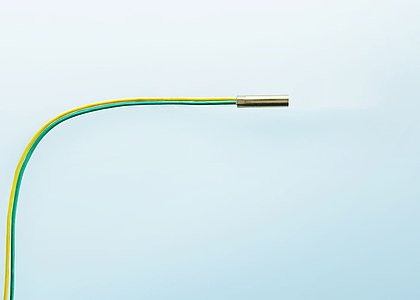

KTY with metal sleeve and roll squeeze

Here, the measuring resistor and the feed are connected firmly to the sleeve by beading. The advantage of the roll squeeze is that there is a continuous seal of the internal measuring resistor. That means that these temperature sensors are better protected against external environmental influences, such as penetration by condensation.

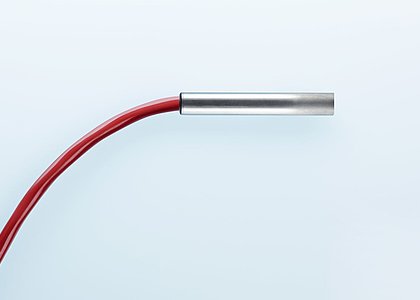

KTY with metal sleeve and casting

In the casting process, the measuring resistor incl. feed is installed in the sleeve head with a casting compound. Different casting compounds are used depending on the sensor type and application. Duroplasts (epoxy resins), elastomers (silicones) or quartz powder are used as standard. The sensor is thus even better protected against penetration by moisture or other liquids than when a roll squeeze is used.

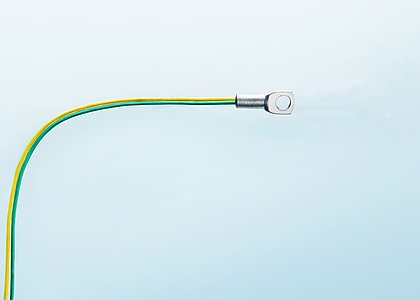

KTY with cable shoe

Here, the measuring resistor and the feed are sealed in a cable shoe. This construction is especially suitable for surface temperature measurement, particularly where there is also a requirement for high voltage-resistant insulation and good thermal contact with the measuring point.

Download certificates

Certificates

ATEX (Deutsch)

pdf 226 KB

ATEX (Englisch)

pdf 215 KB

CCC

pdf 861 KB

IECEx 14.0058 U

pdf 297 KB

INMETRO

pdf 1 MB

EAC

pdf 2 MB

UL CSA

pdf 241 KB

Manuals

Deutsch

pdf 573 KB

Englisch

pdf 624 KB

Russisch

pdf 1 MB

Chinesisch

pdf 601 KB

Brasilianisch

pdf 337 KB

Attestation of conformity

Deutsch

pdf 66 KB

Englisch

pdf 62 KB

Brasilianisch

pdf 65 KB

Französisch

pdf 64 KB