At a glance

Product properties

- Temperature range -200°C … +1100°C

- Tight bending radii

- Various constructions possible

- Short reaction time

Description

Sheathed thermocouples make very tight bending radii possible and are usually used in hard-to-access measuring points. In mineral-insulated sheaths, the thermoelectric wires are embedded in compressed oxide powder, making them vibration resistant. The measured values are therefore not influenced by bending or strong vibration.

Thermocouples have a very diverse range of applications. From reactor construction to laboratories and test plants, thermocouples guarantee precise temperature measurement on the surfaces of vessels, piping, apparatus and machinery, in gaseous and liquid media, and in low and high voltage ranges at low flow speeds.

In the thin-walled sheathed pipe (the wall thickness is approx. 12 ... 15% of the sheath diameter), 1 or 2 thermocouples (depending on the diameter) are pressed firmly into ceramic powder.

The thermoelectric wires are insulated against one another and the sheath as standard. In special implementations, the measuring position can be welded into the sheath. This further significantly reduces the reaction times in gases especially – yet worsens the corrosion resistance of the sheath material. The thermoelectric voltages correspond to the standards IEC 584, Class 2 or DIN 43710. We offer stainless steel or Iconel® as the sheath material as standard.

Sheathed thermocouples are also available in a huge range of constructions: from bare or insulated thermoelectric wire ends to firmly connected compensation lines with a choice of thermoelectric or connection plug, to assembly variants with different connection heads, such as DIN connection heads in form A or B. There are two key differences between the constructions: welded insulated and welded uninsulated.

Assembly variants

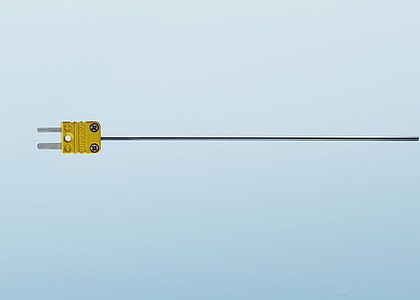

Standard sheathed thermocouple

In the sheathed pipe, 1 or 2 thermocouples (depending on the diameter) are pressed firmly into ceramic powder. Using high-alloy stainless steels and casting the cable transition sleeves also makes the sensors resistant to corrosion. They are used to monitor hydroelectric power turbines, for example.

Sheathed thermocouple “crescent sensor”

In the “crescent sensor” construction, the measuring tip is given a level-concave stainless steel moulded part for particular installation situations. The moulded part is reminiscent of a crescent moon, giving the sensor its unusual name. Here, too, the sensor is pressed firmly into a mineral powder, is highly resistant to pressure and vibration, and can be produced from a diameter of 2 mm.

Sheathed thermocouple “winged sensor”

This construction is ideal for measuring the temperature on pipes as a contact sensor. Called a “winged sensor” due to its appearance, it consists of a thermometer, steel strip wings, insulating top and bottom section, shrinking tube insulation and the associated connectors. The capillary temperature sensor has steel strip wings from the sides. Thanks to the flexible capillary tube, the sensor can be embedded directly into the milled welded sockets and welded firmly to the socket using the “sheet wings” at the sides. This guarantees the optimum thermal coupling. The sensor is then sheathed with ceramic fibre insulating shells and shrink-wrapped with a thick-walled polyolefin hose in order to rule out any influence from the ambient temperature.