At a glance

Product properties

- Mechanically protected in robust metal sleeve

- Moisture-tight version possible (IP66)

- Variable sleeve dimensions

- Preferred construction for IECEx and ATEX approved PTC thermistors

Description

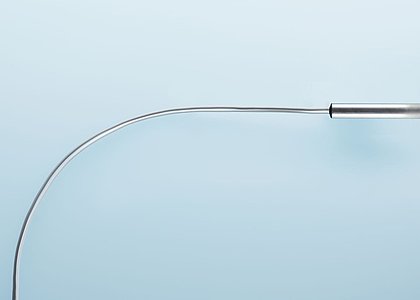

In PTC thermistors with a metal sleeve, the sensor is installed in a metallic protective sleeve made from brass or stainless steel. The thermal conductivity of the metal sleeve guarantees a good thermal coupling to the measuring point. The sensor is connected firmly to the feed using a press squeeze, roll squeeze or casting. Various hose lines or Teflon single wires with various cable cross sections are available as supply lines.

Assembly variants

PTC thermistor with metal sleeve and press squeeze

When hose lines are used instead of PTFE single wires, the sensor is connected with a hexagonal squeeze. Using a viton shrinking tube directly between the squeeze and the feed makes the sensor relatively tight. Where tightness requirements are higher, we recommend the use of roll squeezes.

PTC thermistor with metal sleeve and roll squeeze

Compared to the press squeeze, the advantage of the roll squeeze is that there is a continuous seal of the internal measuring resistor. Double beading on silicone hose lines has proved effective for increased requirements against potential moisture penetration.

PTC thermistor with metal sleeve and casting

In this construction, the PTC thermistor incl. feed is installed in the sleeve head with a casting compound. Different casting compounds are used depending on the type and application. Duroplasts (epoxy resins), elastomers (silicones) or quartz powder are used as standard. Temperature sensors constructed in this way are then cured and aged in special temperature ovens.

PTC thermistor with cable shoe

Cable shoe constructions are very easy to install in any location using a screw – with no need for the sometimes complex mounting processes for common constructions with round housing or sleeves. Clamps or plugs specified by the customer can be installed as options. Insulated or uninsulated cable shoes can be used, depending on the temperature resistance required.

Download certificates

Certificates

ATEX (Deutsch)

pdf 226 KB

ATEX (Englisch)

pdf 215 KB

CCC

pdf 861 KB

IECEx 14.0058 U

pdf 297 KB

INMETRO

pdf 1 MB

EAC

pdf 2 MB

UL CSA

pdf 241 KB

Manuals

Deutsch

pdf 573 KB

Englisch

pdf 624 KB

Russisch

pdf 1 MB

Chinesisch

pdf 601 KB

Brasilianisch

pdf 337 KB

Attestation of conformity

Deutsch

pdf 66 KB

Englisch

pdf 62 KB

Brasilianisch

pdf 65 KB

Französisch

pdf 64 KB